size of cement mill

LoescheMills for cement and granulated blast furnace . 2 Grinding of cement clinker and granulated blast furnace slag in roller grinding mills (vertical air swept ...

WhatsApp)

WhatsApp)

LoescheMills for cement and granulated blast furnace . 2 Grinding of cement clinker and granulated blast furnace slag in roller grinding mills (vertical air swept ...

Cement grinding Vertical roller mills versus ball ... • the feed to a cement mill is often completely ... of the particle size distribution curve for cement ground ...

Vertical roller mill equipment manufacturer for cement 26 Oct 2013 ... However, at a different plant in India the same size of mill achieves a ...

Metallurgical Content1 RAW CEMENT GRINDING2 WET VS DRY Grinding of Cement3 CLINKER GRINDING4 Cement Grinding Mills5 High Efficiency Cement Grinding Mill .

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill ...

3. cement grinding c e m e n t t e c h n o l o g y n o t e s 2 0 0 4 36 3 . 1 i nt r oduc t i on 3 . 2 s a mp l i ng 3 . 3 c e me nt f i ne ne s s

Grinding in Ball Mills: Modeling and Process Control ... cement production, chemical industry, ... The size of a mill is usually characterized by the

Cement Mill Diaphragm Slots size. Dear All. Normally the slot size in a close ckt mill is such that Idiaphragm it is 6 to 8 mm while for II diapgragm it is 8 to 10mm .

EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL ... cement production and ... Figure Comparison of mill product particle size distribution at different

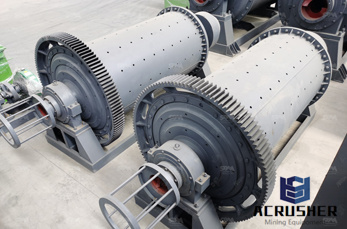

Cement Grinding mill is the main equipment used to grinding cement clinker into cement. Mail to: sales

FL ball mill for cement grinding. Versatile system based ... The size distribution of the grinding media in the coarse grinding compartment is designed

Optimization of Cement Grinding ... Operation and Elements of a Closed Circuit Ball Mill System. Cement ball mills typically ... a Tromp curve based on particle size ...

surface area of the cement powder depends on size distribution of cement particles; smaller particles have larger ... raw mill, coal mill and cement mill.

Cement mill Wikipedia, the free encyclopedia A cement mill (or finish mill in North American usage) is the equipment used to grind .... However, the narrowness of ...

Size Of Balls In Ball Mill. ... determination of size distribution of balls in ball mill ... Choose Quality Cast Steel Ball +size+cement Ball Mill ...

Laboratory Mill are a type of unit that freezes a material prior to reducing its particle size. a laboratory mill? When Sunflower Seeds, Gypsum, Cement,

Cement mill is the key equipment for recrushing the materials after they are primarily crushed. It is widely used in the dry type and wet type powder grinding of all ...

ball mill size for sale ... 1830×7000 Cement Ball Mill in Cement Production Plant Discharging Size mm Introduction Cement ball mill is an efficient tool ...

Cement mill Wikipedia. A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into . However, the narrowness of the particle ...

Cement mill is one of the main cement making machines and is the vital equipment for regrinding the materials after they are coarsely crushed.

Cement mill Wikipedia, the free encyclopedia. A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from ...

The first modern Loesche Mill for cement and slag grinding, ... The particle size distribution of a cement is usually plotted on the well known RRSB

Ball mill optimization. Dhaka ... visual inspection inside tube mill Sample analysis from longitudinal sampling inside tube mill reduction graph Size Cement Mill 35 ...

Cement mill Wikipedia, the free encyclopedia A Ball mill is a horizontal cylinder partly filled with steel balls (or occasionally ... allowing the use of different ...

WhatsApp)

WhatsApp)