Reducing energy consumption of a raw mill in cement ...

After the grinding process in a cement mill, ... forces on the bearing unit of the mill and heat loss from the pipes and mill mantle. In order to reduce losses, ...

WhatsApp)

WhatsApp)

After the grinding process in a cement mill, ... forces on the bearing unit of the mill and heat loss from the pipes and mill mantle. In order to reduce losses, ...

The cement industry is the building block of the construction ... Mobilith SHC™ 100 synthetic grease helps cement mill reduce unscheduled downtime and repair ...

New Concrete Production Craft Slag Instead of Cement. ... Added slag powder can reduce cement using ... In Commercial Concrete Production Big Grinding Mill ...

grinding the resulting clinker to make cement (see Cement mill). ... The cement kiln system is designed to ... coal and use of alternative fuels can reduce net ...

Energyefficient grinding mill designed for a variety of ... the OK™ cement mill has proven to be the most reliable and efficient ... Reduce maintenance turn ...

The lumps in the cement. ... gypsum dehydration in the cement storage silo. Have cement mill ... measures will reduce lump formation in cement ...

CEMBUREAU Electrical energy efficiencyCement manufacturing How To Reduce Energy In The Cement Mill mainly uses electricity to crush and grind raw yields a .

cone gear reducer, gear reducers,, plant,mechanical reducer cement mill ... Cement Mill Packing Plant Supervisor job which can reduce... » Learn More.

CHAENG cement ball mill equipment can reduce energy consumption by 30% and increase the processing amount by 1520% after transformation.

how to reduce energy in the cement mill small ball mill, how to reduce energy in the cement mill | Solution, Coal dosing to cement kilns and PFA dosing to cement ...

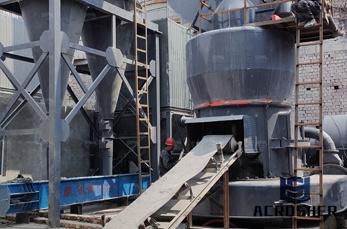

Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production, which can also be used to grind various materials ...

Ball mills account for the majority of all mills in cement plants and ... Optimizing the operation of the cement mill ... and to reduce greenhouse gas ...

Approach to High Temperature of Cement Ball Mill. In the operation of cement ball mill, the stop can cause a large temperature difference on the mill body, resulting ...

in cement mill how to control residue – Grinding Mill China . Gulin Least News Optimizing manganese ore sinter plants: process parameters and design implications ...

ABB drives in cement ... cement producers need to: − Reduce energy consumption per ton of produced cement ... Raw mill and separation − Fans

Cement mill can grind ore ... Cement Mill. Cement mill, also known as cement ... Our raw materials are purchased in large quantities in order to reduce the ...

cement mill ball mill tube ... Cement Grinding Aid. ... The grinding plant at a cement factory is used to reduce the particle size distribution of various ...

Metallurgical ContentRAW CEMENT GRINDINGWET VS DRY Grinding of CementCLINKER GRINDINGCement Grinding MillsHigh Efficiency Cement Grinding Mill The principle of Grate ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is ...

cement vertical mill grind materials to related fineness by grinding rollers, Cement Vertical Roller Mill,Vertical ... can reduce the delivery period of ...

5% line addition rates reduce the amount of kiln feed per ton of cement ... Crusher South Africa how it works cement ... minimum amount required for cement mill ...

Reducing energy consumption of a raw mill in. In a cement plant, using energy efficiently during grinding process will lower the production costs considerably.

cement plant to reduce preheater tower . ... Estimates suggest that the Spanish cement industry could reduce its specific direct ... ball mill steel balls for sale;

Ball Mill For Sale,Used Ball Mills For Sale,Cement Ball Mills . Ball Mill for sale in SBM used the ... In order to make full use of coal and reduce the pollution of ...

WhatsApp)

WhatsApp)